Rotor Blade Inspection

With the SYSWE inspection service for more yield for your wind turbine

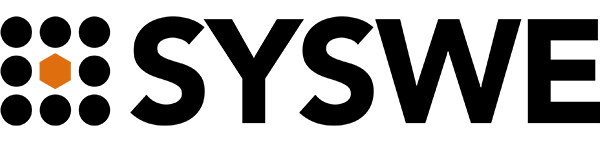

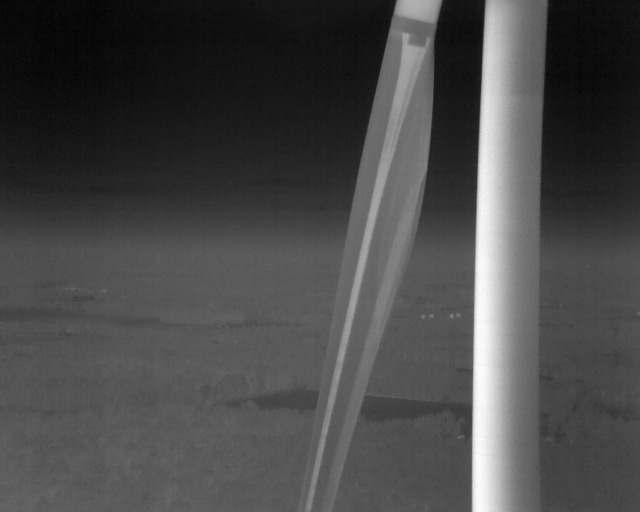

The non-contact methods for inspections of the rotor blades

- optical methods for inspecting the surface of a rotor blade such as damage to the aerodynamic shell, laminate damage or damage to the fiber reinforced composites, damage to sandwich structures, adhesion defects, damage to the lightning protection system and the assessment of passive flow elements (vortex generators, etc.) )

- and thermographic methods for detecting damage within the structure of a rotor blade such as air pockets, delaminations and ondulations as well as adhesion defects.

The optical and thermographic methods are executable from air, from ground and during manufacturing

The rotor blades of a wind turbine are subject to heavy loads due to the emerging operational loads and the additional environmental influences. Because of that and the handcrafted manufacturing process the rotor blades can cause damage, which can lead to loss of earnings, high downtimes, even to the total loss of the wind turbine and to the public endangerment.

With the latest drone technology, the SYSWE inspection service supports your rotor blade inspection. Through a drone-based condition test of the rotor blades, cable access technicians or industrial climbers get an idea of the actual condition of the rotor blades and are able to work more time-saving and targeted. In addition the downtime of the wind turbine is shortened. The following table compares the rope access technique with the drone inspection.

| Rope access technique | Drone-based inspection | |

| Wind turbines per day | 2 | 4 |

| Downtime per wind turbine | 6 h | 2 h |

| Personnel costs | 100 % | 50 % |

| Price per wind turbine | 100 % | 50-70% |

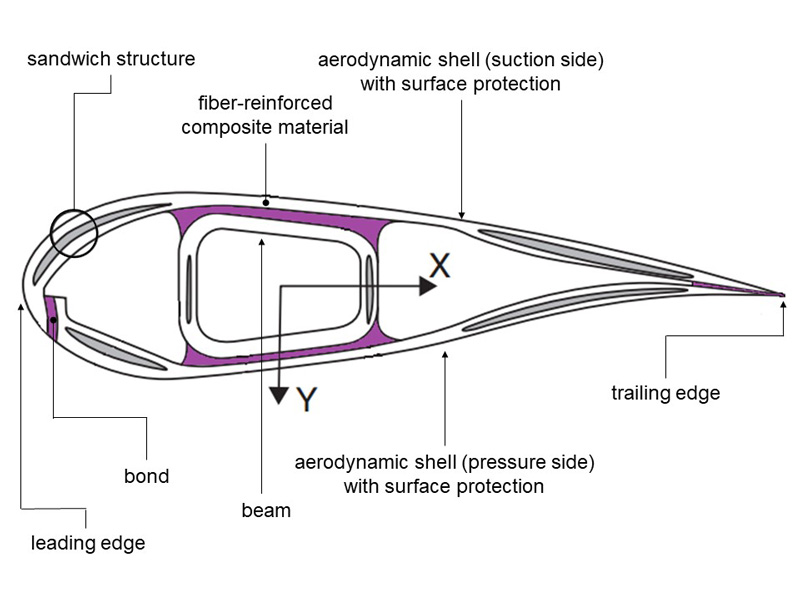

Rotor blade structure and materials

The aerodynamic shells, which form the pressure and suction sides of a rotor blade, and the webbing-web construction are made of fiber-reinforced composite material. Fiber reinforced composite material is a composite of fibers that substantially compensate for material stresses and a matrix that acts as a sheath and substrate. Dominant fibers for the production of rotor blades are glass and carbon fibers. Carbon fibers being used exclusively for reinforcing highly stressed areas. The aerodynamic shells are also coated with a surface protection, the so-called gel and topcoat. Furthermore, sandwich structures are implemented in the rotor blade. These structures consist of a stack arrangement of two cover layers and a filling material located therebetween. The aerodynamic shells are glued over the leading and trailing edges with the belt web construction to form a complete rotor blade.

Damage to the aerodynamic shell

The forming aerodynamic shell, which consists of the pressure and suction side, is coated with a surface protection, the top and gel coat. Due to material or production-related and / or environmental influences, the protective layer may fail. When this occurs, the underlying fiber reinforced composite is exposed to environmental conditions. Further damage to the skin is:

- Top and gelcoat damage

- Leading edge damage (damage to the leading edge protection foil)

- Leading edge wear (erosion)

- Trailing edge damage (breakage of the trailing edge, open trailing edge)

- Holes

- Pore and voids

- Lightning damage from lightning strike

- Cracks

Damage to the fiber-reinforced composite material

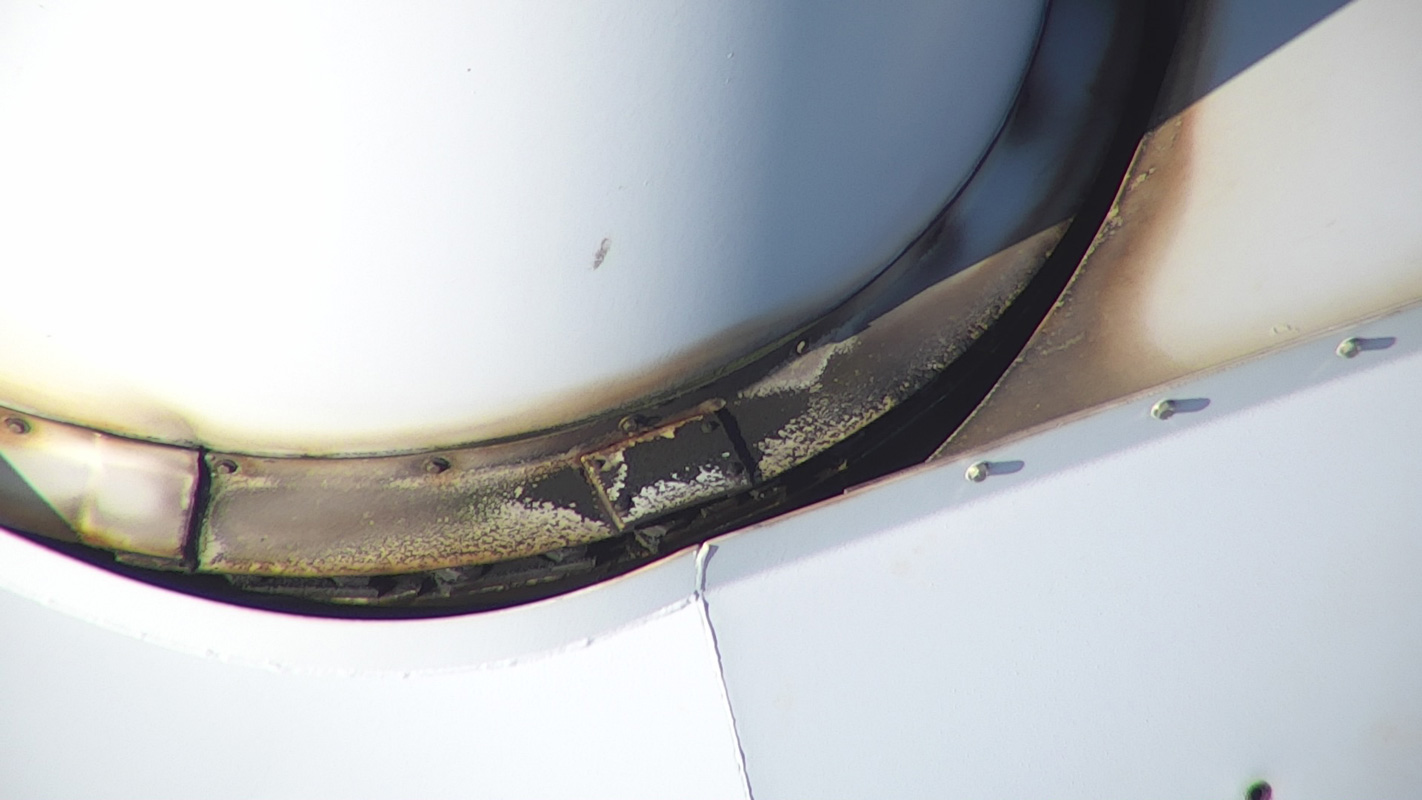

Damage in the fiber-reinforced composite can be caused by a worn top and gelcoat layer, as the laminate is now exposed to environmental factors. Lightning strikes that hit the laminate leave burns in the fiber-reinforced composite material and promote spider web-like cracks. Overview of laminate damage:

- Delaminations

- Ondulations

- Burns and spider web-like cracks caused by lightning strikes

- Dry laminate

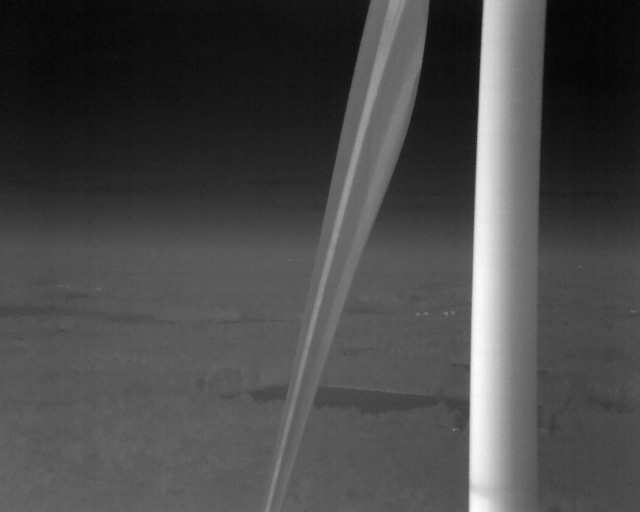

Defects to adhesive seam

Bonding defects usually arise during the bonding process of the structural components of a rotor blade and thus prevent a homogeneous flow of force. Under operating loads and the additional environmental influences that act on a rotor blade, the still intact adhesive joints can break adhesively or cohesively. Gaping cracks on the leading edge of a rotor blade indicate, for example, a defective bond. This may have been caused by delaminations in the web, which leads to higher loads on the leading edge.

Damage to lightning protection systems

Rotor blade lightning protection systems have the task to dissipate the lightning current via a low-impedance line with the aid of suitable lightning arresting devices and thus to reduce the damage in the impact points. In order to ensure proper lightning discharge and surrounding material is not affected from the impact of a lightning strike, it is necessary to recognize lightning protection system damage early.

Typical designs of rotor blade lightning protection systems are copper wire braids, metal tips or caps, metal receptors and metal profiles.

Damage to flow elements

To optimize the aerodynamic, aeroelastic and aeroacoustic properties of a rotor blade, flow-influencing measures are used – so-called passive flow elements. With passive flow elements an increase in performance, load control and noise reduction can be achieved. Therefore, a state check of these flow-influencing elements is of high importance.

Common flow elements are: Vortex-Generators, Zig-Zag- or ZZ- turbulator tapes, Serrations/Dino Tails, Gurney Flaps and Stall-Strips.

Damage Classification

For the classification of damage to rotor blades, SYSWE uses a damage class system consisting of 5 damage classes. Each damage class includes a description of the damage and an action request. Some examples of damage to each class are also included.

| Class | Designation | Call to action | Damage pattern |

| 1 | slight damage | no measure/action are necessary | small damages / defects in the top coat and areas with small pores |

| 2 | slight significant damage | a repair is recommended | Gelcoat damage without exposed laminate; Topcoat damage |

| 3 | significant damage | a imminent repair is necessary | Grease and oil spills; visible laminate gelcoat damage (matrix has no resistance to UV radiation); gelcoat eruptions at the trailing edge (cause of noise emissions); longitudinal cracks at the front or rear edge; transverse cracks on the aerodynamic shell; open front or rear edge; damage to the erosion protection film |

| 4 | very significant damage | the damage should be repaired as soon as possible | Longitudinal cracks at the front or rear edge; transverse cracks on the shell exceeding a critical length; open leading or trailing edge exceeding a critical length; lightning damage that consequential damage is possible |

| 5 | critical damage | the immediate stoppage of the wind turbine must be initiated | Damage due to a lightning strike; all structural damage that can lead to leaf failure |