Generate the highest possible returns – with SYSWE

- We check your photovoltaic system to defect cells, modules, hotspots or delamination and defect bypass diodes

- It is necessary to check your system periodically so that it works correct and uninterruptible, to generate the highest possible earnings

- As accepted expert for photovoltaic systems as well as accepted expert for electro thermography (VdS) and certified for disturbance-free testing after DIN EN ISO 9712 class III, we are your competent contact

Why it is so important to check the photovoltaic system?

Every minute a photovoltaic system operates with reduced output, because of

- defects

- processing defects

- material defects

- degradation

implies significant costs for the operator.

In addition a regular check and maintenance of the photovoltaic system is prescribed after DIN VDE 0105-100 from october 2009 for commercial users. This check has to be performed by a skilled electrician. SYSWE offers all inspections from one provider with professional measurement equipment. After the inspection you will get a complete inspection report and if there is a defect, also an improvement reference or maintenance instruction.

Frequently error pattern at a photovoltaic system

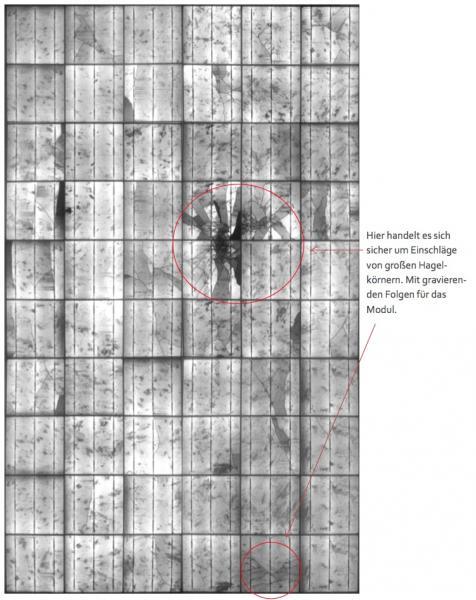

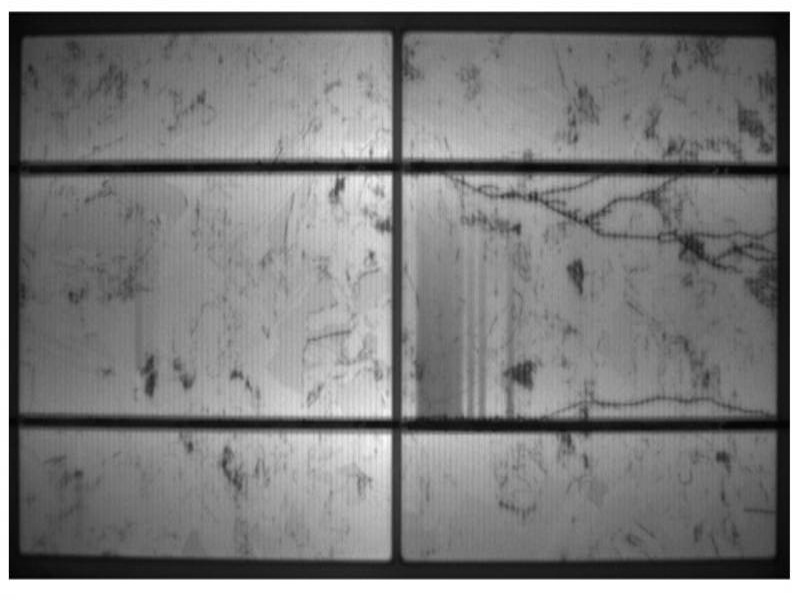

Defect cells

Possible causes for this error pattern are cell breakage or micro-fissures. With progressive expansion of the rupture cell breakage can occur, whereby the produced electricity can’t be taken away. The missing contact get’s clearly visible with the electro luminescence measurement.

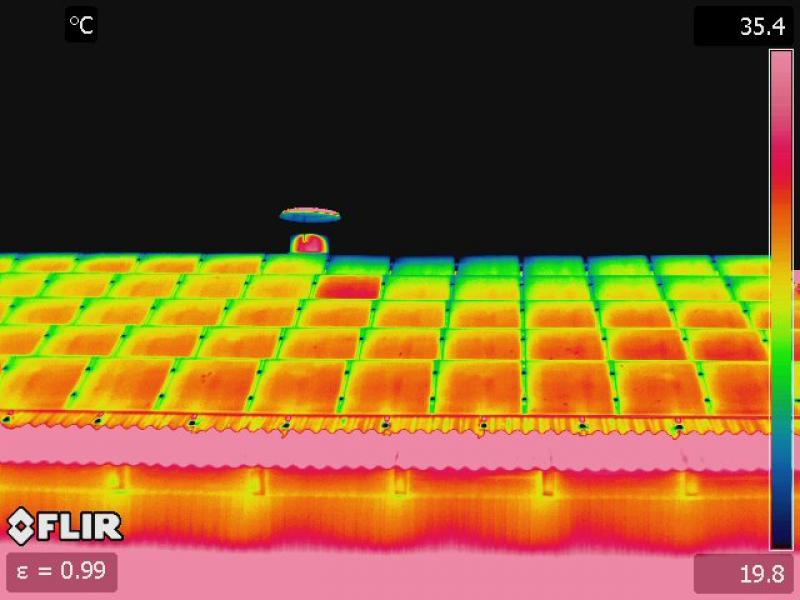

Hotspots / burn spots on the module

Hotspots can occur by an opacity of the plant, e.g. by overleaf trees, a massive pollution of the modules or by ingrowth of grasses or bushes at open-area installations. The shaded area lead to a strong local heating and a permanent damage of the module or the string, what results possibly in a reduced performance of the string.

Defect modules

Not only individual cells can be functionless in a module. In the circumstances a failure of whole modules in a solar system is possible. With the help of a thermographic image, defect modules can be detected, because the defect module differs massive in the colour representation of the thermogram.

Delamination

The solar cell is embedded in the reverse foil, the so called EVA foil. This foil protects the cell against UVA radiation and weather conditions. If there is a separation between the solar cell and the EVA foil, cell corrosion and performance losses could occur.

Defect bypass diodes

For the protection against the hotspot effect bypass diodes are obscured in the modules. They have the purpose to decouple shaded areas from the rest of the cell to save them from hotspots. By defect diodes or partially shaded modules at simultaneously inactive diodes hotspots can occur.

We offer the following test methods:

Thermography

Thermography is an imaging method to illustrate surface temperatures of objects. The temperature difference in the module respectively in the whole system is illustrated with the high-resolution infrared camera.

Characteristic curve measurement

With the characteristic curve measurement device we can determine values like the actual performance, the short-circuit current as well as the open circuit voltage and convert them into standard test conditions (STC). From the comparison of the actual and the reference characteristic curve we can draw conclusions to the condition of the photovoltaic modules.

Electroluminescence measurement

At the electroluminescence measurement we use a high-resolution camera to illustrate defects that are not visible with the naked eye. The system can be checked in operation. Visible defects are:

- capillary cracks of the silicon wafers

- damages by hail

- defective edge insulation of the solar cell

- break of the contact finger

Flashing of the modules

Flashing the modules is used to determine the rated power of a solar cell or of a solar module. With this the power loss of a module and thereby of the whole system can be detected.

Rooftop electroluminescence

For this measurement method there is no disassembly of the modules necessary – they were checked on the spot. SYSWE is one of the first providers in Germany who has the ability to check your system in the night. Therefore a framework with the measurement device is drawn on the module. Only when the defects are too strong the module has to be disassembled and can be checked in our mobile test laboratory.

Insulation resistance measurement

PV systems with transformerless inverters are not galvanic separated from the grid at feed-in operation. According to the VDE standard DIN VDE 0126-1-1 a certain limiting value of the insulation before grid connection must be observed. The limiting value is geared to the current installation instructions.

Because of the increasing plant size and in consequence the major generating surface as well as the parallel connection of the modules, the insulation resistance is decreased. This maybe implicates that the inverter is not allowed to connect to the grid, although the system operates proper.

Expert activities

We perform complete inspections of solar systems and assume the transaction with your insurance!

Why we are the right business partner?

- We are certified expert on photovoltaic systems (VdS)

- We are certified expert on electrical thermography (VdS)

- We are certified for non-destructive tests after DIN EN 473 IT level 2 all classes

- We have the certificate after DIN EN 473 IT sector E – electrical thermography

- We have the certificate after DIN EN 473 sector I – industry thermography

- We have the certificate after DIN EN 473 II sector B – construction thermography

- We have the certificate after DIN EN 473 IT I sector B, E, I – Thermography level 1 (building-, electrical- and industry thermography)

- We have the FLIR-certificate for building thermography

- We are equipped with modern technology / measurement devices

- We have over 10 years experience in check of renewable energies (photovoltaics, biogas plants, thermography, Blower-Door, gas camera)

- We provide survey reports for insurances and handle the transaction

SYSWE is your partner for all relevant inspections of your photovoltaic system. We also assume the transaction with your insurance, so you have a minimum effort. As accepted expert for photovoltaic systems and accepted expert for electro thermography (VdS) and certified for disturbance-free testing after DIN EN ISO 9712 class III, we are your competent contact.